Fairport Engineering Ltd of Adlington, Lancashire has been working on the Lynemouth power station conversion project since 2016 as the main contractor’s, SRM, specialist materials handling engineer and designer thus allowing this land-mark project to benefit from the combined strengths of both organisations. This major multi-million pound project is totally focussed on replacing the previous fuel (coal) handling and storage systems with a new regime that will be suitable for biomass (wood pellets). Whilst this conversion from one form of solid fuel to another requires major investment in the fuel handling systems it also needed new ash handling facilities. Two types of ash will be produced once in operation : Bottom Ash direct from the boilers and Fly Ash from the filtration systems.

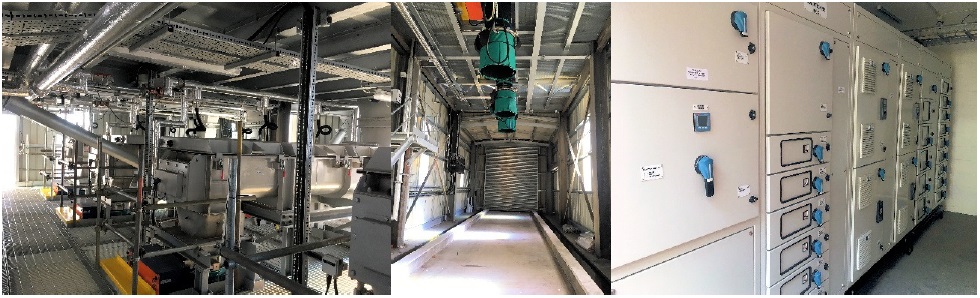

Fairport was commissioned directly by Lynemouth Power to provide a conditioning system for the finer Fly Ash. This consisted of drag link conveyors, silos, duplex discharge screw conditioners and screw conveyors to transport, store, condition and deliver the ash into skips for onward disposal. The new system is located in the same position as the existing facilities and utilises the existing structure, suitably adapted and refurbished, but with only two new holding silos. The drag link conveyors and screw conditioners and screw conveyors have been provided by Fairport Engineering’s sister company Fairport Process Equipment Ltd. Recently completed after a six month construction period the conditioning facility is currently being commissioned.

For more information please contact :

Linda White : Marketing & Communications Manager

Tel : 01257 484000 E Mail : LWhite@fairport.co.uk