3D scanning helps Greenbank deliver biomass contract

A large biomass-fuelled power plant is set to benefit from a host of additional safety features supplied and installed by the Greenbank Group. The Derbyshire-based firm has been awarded a major contract to retrofit the UK plant with quick shut valves, isolation valves and associated chute modifications. The contract covers the design, manufacture and installation of the equipment and as part of the project Greenbank has carried out a comprehensive survey of the site using state-of-the-art 3D scanning technology.

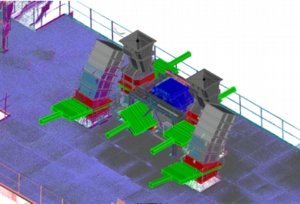

Charles Conroy, Greenbank Managing Director, explained: “We used specialist 3D scanners to create an accurate representation of the existing plant and our design proposals were then overlaid onto these ‘virtual’ plans, to show how they would look once installed. “This technology, operated by our trained engineers using Greenbank’s own laser scanning equipment and software, will continue to be used throughout the installation process, generating graphic models of the components for review ahead of manufacture by Greenbank’s in-house team.” The new chutes and valves are due to be delivered to the plant early in 2021 with installation taking place through the year, in line with the client’s requirements. When operational, the new valves will be capable of containing any safety critical incident within the conveying/storage equipment, providing safe isolation of the plant during maintenance. “The work will be carried out during a series of short outages at the plant to minimise the impact on the operating regime,” Mr Conroy added.

“This technology, operated by our trained engineers using Greenbank’s own laser scanning equipment and software, will continue to be used throughout the installation process, generating graphic models of the components for review ahead of manufacture by Greenbank’s in-house team.” The new chutes and valves are due to be delivered to the plant early in 2021 with installation taking place through the year, in line with the client’s requirements. When operational, the new valves will be capable of containing any safety critical incident within the conveying/storage equipment, providing safe isolation of the plant during maintenance. “The work will be carried out during a series of short outages at the plant to minimise the impact on the operating regime,” Mr Conroy added.

Tel: +44 (0)845 0707 097

Email: info@greenbankgroup.com