The challenge of producing concrete products with lower carbon footprints is an issue the construction materials handling and producing sectors have been seeking to take on with a range of innovations of late, with precast concrete firm FP McCann producing a UK first new product developed with the help of its international partners.

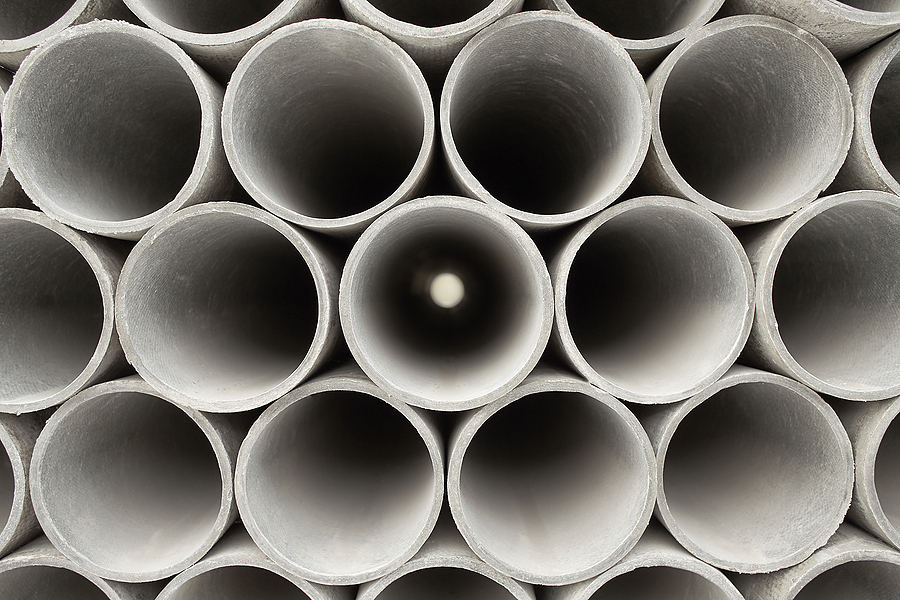

It has become the first company in the UK to make precast manhole rings by using Wagner’s Earth Friendly Concrete (EFC), which makes use of a geopolymer low-carbon binder instead of Portland cement. The result is that the production process generated 80 per cent fewer carbon emissions.

At the same time, EFC cement provides comparable strengths to normal concrete and greater durability in some harsh environments due to the chemical composition of the binder. The geopolymer is made from a mix of fly ash and granulated slag from blast furnaces.

FP McCann, which has its factory at Knockloughrim in Northern Ireland, said the next step will be to use the same kind of concrete in the precast sector. It said that “low carbon alternatives can combine with modern manufacturing methods to provide a truly innovative solution for the construction sector”.

This process evidently comes with significant benefits, not least the practical utility that comes with the re-use of the granulated slag material from furnaces.

FP McCann’s development is the latest in a number of new efforts to make concrete production and the construction sector less carbon-intensive, with many firms committed to further development in this direction.

Last month, 17 major construction firms, property companies and developers signed up to the ConcreteZero initiative, an initiative that pledges them to achieve net zero concrete production by 2050. Interim targets along the way include a 30 per cent cut in concrete emissions by 2025 and a 50 per cent reduction by 2030.

Among those signed up are construction firms Laing O’Rourke, Mace, Skanska UK and Willmott Dixon, plus engineering firms Buro Happold and Thornton Tomasetti.

Bulk material handling companies can strengthen their position with MHEA membership. Get in touch with us today to find out more.